Our Focus

Our Prestigious Customers

Frequently Asked Questions (FAQ) - Facility Management Services for Clients

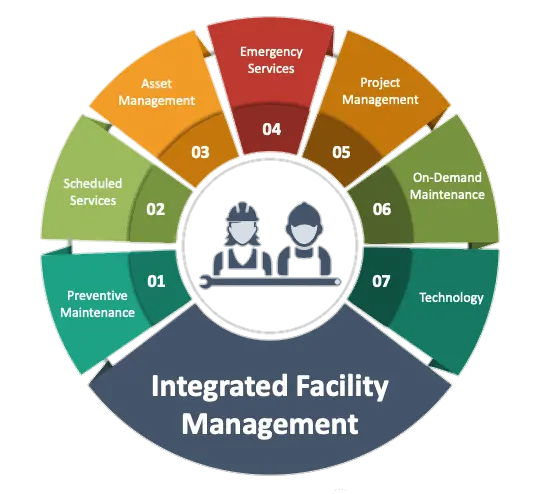

Facility Management is a comprehensive approach to maintaining and optimizing the physical assets and infrastructure of a business.You need it to ensure your facilities run efficiently, reduce operational costs, and create a safe and comfortable environment for your employees and clients.

Facility Management companies offer a wide range of services, including maintenance, security, cleaning, landscaping, energy management, waste management, and more. We tailor our services to meet your specific needs.

Facility Management can benefit your business by improving productivity, reducing downtime, lowering operational costs, enhancing safety and security, and maintaining a positive and professional image.

The cost of facility management services varies depending on the scope and complexity of your needs. Companies typically offer tailored pricing models. It’s best to request a quote or a consultation to get an accurate estimate.

Facility management experts can conduct energy audits and implement strategies to optimize energy usage, reduce waste, and lower utility costs. This includes the implementation of energy-efficient systems and practices.

To get started, Reach out to our esteemed company SHREEM IFM SERVICES, schedule a consultation, and discuss your specific needs and goals. They will guide you through the process of customizing a solution that aligns with your business objectives.